Conducrete

Conducrete saves time, money and lives for customers. Being one of the most rigorously tested and trialed products in the history of the electrical safety sector it is independently proven to offer a lower electrical resistance than the historical first choice premium brand. It is also faster to install for two very good reasons, less of it is required to be used therefore less installation time is required, but in many applications it does not even require water to be added. When this is compared to the greater volume required of its main rival, along with potentially other additives as well as water results in Conducrete reducing costs even further. It is no secret that for most large consumers the per bag price may be slightly higher, but buying a cheaper product on a per bag level is an unbelievably false economy. Taking such claims on face value is unlikely in the construction industry and to verify Earthing Services’ claims one of the largest telecommunications companies in the world tested the product endlessly and not only evidenced a 60% increase in efficiency in the earthing of the deployment, but also a saving of many millions of pounds. Rarely are products as good as people claim, but Conducrete is the exception.

From earthing without rods, to the best way to protect deep electrodes: Conducrete is the best

Conducrete enhances the performance, reliability, and longevity of earthing systems.

Once installed and cured the Conducrete electrode surround:

- Creates excellent contact with surrounding ground mass.

- Reduces impedance (larger electrode surface area), and reduces the resistance.

- Reduces Earth Potential Rise, step and touch potentials.

- Prevents theft and corrosion.

- Conducrete is environmentally neutral and has been installed in environmentally protected areas.

Conducrete is ideal for a range of applications

- Deep vertical electrode earthing.

- Horizontal electrode earthing.

- Distribution earthing.

- Transmission earthing.

- Substation earthing.

- Earthing system retrofits.

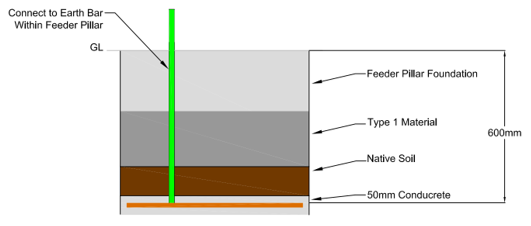

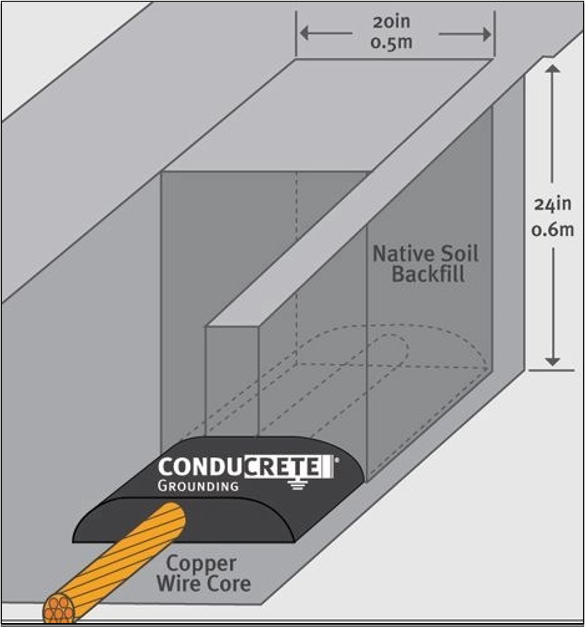

Horizontal conductors

Horizontal conductors can be installed in minutes, and even in cable supply excavations. They are a highly effective method that avoids the need for boreholes and their respective restrictions and cost implications. Usually installed by simply opening the bag and laying it in the excavation dry to encase the interconnection conductor. In many applications Conducrete has either been used beneath, or served as the structural foundation of a given element.

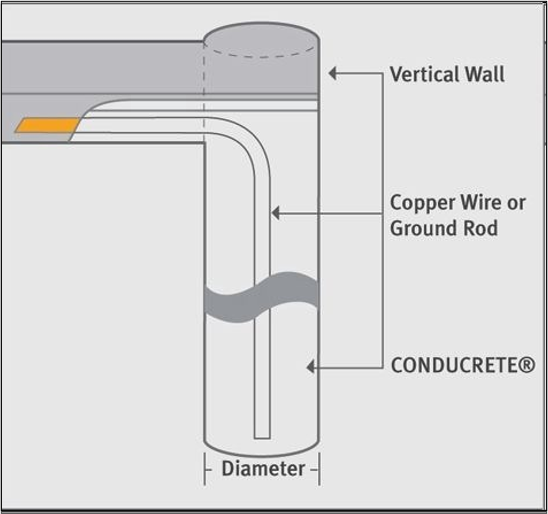

Vertical conductors

In limited footprint areas where a low resistance must be achieved then occasionally the only way to go is down, fortunately Conducrete boreholes are usually much less demanding than using conventional products due to the superior performance attributes of the product. In many applications Conducrete has either been used beneath, or served as the structural foundation of a given element.

Why do earth rods deteriorate?

The most commonly installed variety of earth rods is copperbonded steel cored. The tip and end of the rods are exposed steel as is any location on the surface of the rod where the copperbond has been scratched deep enough to penetrate the thin covering of copper. Steel corrodes, and at any area on the earth rod where the steel is exposed there is a potential source of corrosion. The rod will deteriorate in line with the relative acidity, alkalinity, salinity or toxicity in the surrounding mass of earth. So even a perfectly installed rod in non-aggressive soil will be subject to deterioration over time, at the very least at the tip and end, which means that the steel will “rot” from the inside of the rod, outwards.

This is not an issue of well-made rods versus poorly made, or cheap rods. This is all copperbonded steel rods. The image to the right of this section is of a UL approved earth rod manufactured by one of the leading global brands. This photograph was taken three (to be clear: 3) months after it was installed. In this instance salt water migration caused the aggressive deterioration, but there was no outward evidence anything was wrong. That is the worrying point about earth rods. They may have significantly deteriorated leaving a site exposed to dangerous levels of fault current and with no ways of protecting against them. It is for this reason that permanent earthing systems that will prevent corrosion of metallic elements are increasingly accepted as necessary.

Proven to be the best, and relied upon by the best

Conducrete is a conductive concrete, which creates safe zones in areas where traditional methods are unsuitable, components stolen, or enhanced safety is required. Conducrete helps to create safe systems where before there would be threats to life. The applications of Conducrete are vast and in a wealth of Earthing Services’ projects it has demonstrated astounding theft-resistance of metallic elements. The versatility of this product makes it difficult to provide an exhaustive list of its capabilities; new applications for Conducrete are being discovered frequently.

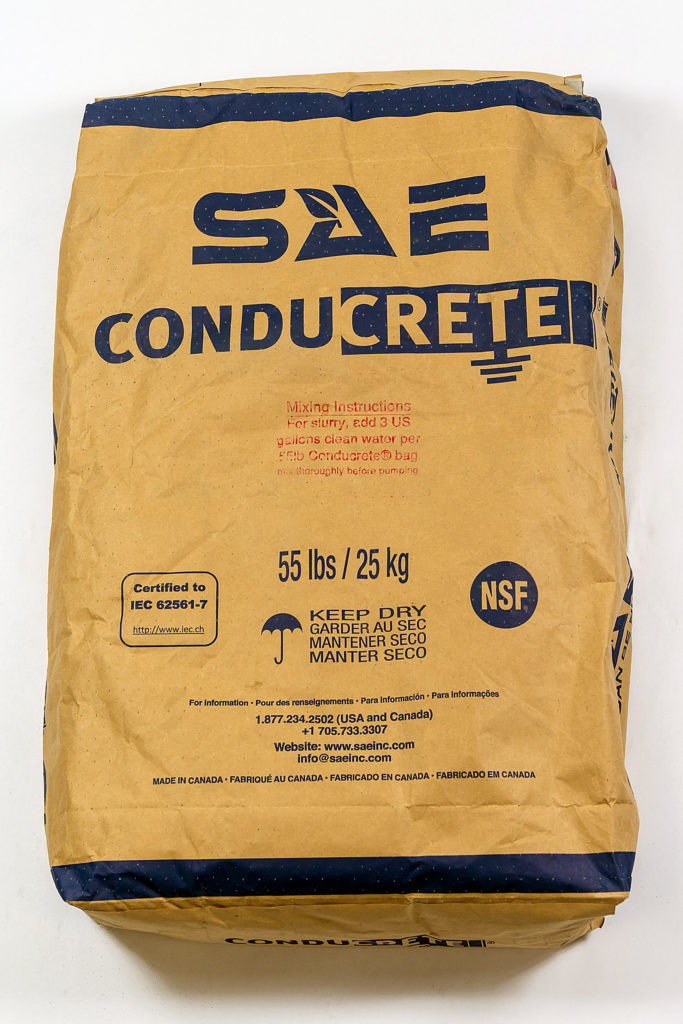

Conducrete is provided in powder form and is available in 25kg bags. It is easy to install dry directly from the bag, or mixed with water in a slurry format and pumped into the trench or hole.

Conducrete adds substantial protection to any system where low impedance earthing is required and it has been successfully utilized to enhance and protect earthing systems across many industries including the following: Electrical Utilities, Telecommunications, Broadcasting, Wind Farms, Mining, Oil and Gas, Industrial and Manufacturing, Municipal and Institutional and Military.

One of the original earthing enhancement backfills was called bentonite, you can still buy it today and it is a kind of clay. The most common uses of bentonite are for cosmetic products and for cat litter. Even though the practical part of the construction industry has moved on there are a few devotees (as that analogue in a digital age mindset persists) and also in a number of heavily outdated specifications. A recent client contacted us to help them update their electrical specifications when they realised how outdated the reference to bentonite made it; it seemingly hadn’t been updated since the 1970s…

In any event the following short clip should provide an overview for how bentonite compares with the technological advances of Conducrete.

Corrosion of direct buried steel - solved

Corrosion of direct buried steel is an endemic problem with any power transmission infrastructure, and many elements within its vicinity. Fortunately we have developed a patented method incorporating our Conducrete product that prevents any deterioration, provides structural stability and of course the superior standard of electrical earthing performance that our clients have come to expect.