Innovation

It is commonly observed in the construction industry that lightning protection and electrical earthing hasn’t changed since the time of Benjamin Franklin and his experiments with kites and wires. This underlines the difference between Earthing Services and other companies. You may encounter companies that hold the view of “no change” but that should be a clear warning sign that it may not be the best organisation to support your needs. The truth is that the available knowledge about the behaviours of electrical current, and how best to protect lives and assets from it, has increased dramatically, and as such the best methods for managing it have improved in turn. That being said cynicism can be justified when even some of the most respected design teams in the international industry continue to specify the same varieties of system that they have for decades without sufficient consideration reducing health and safety risks to installation teams, to protecting systems from theft, or how to design with greater sympathy for footprint or sub strata site constraints. Earthing Services always seeks to specify the most cost-effective system that will last indefinitely. The very best way for any company to make the most of its relationship with Earthing Services is to be as forthcoming as possible with their requirements and what they would ideally like to achieve.

e5's Earthing Innovation podcast

It was both a pleasure and an honour to be invited to contribute to the e5 Group podcast on earthing innovations.

Some of our innovative solutions

Below is a sample of our innovative solutions, but do not let these constrain your thinking, if you have a problem or even a desire to change, just get in touch.

Earthing in rocky environments

When it comes to safely dispersing electrical current rock is as challenging an environment as you are likely to encounter. Having inherently high resistivity rock-type areas make managing fault current a more difficult task. Using traditional metallic conductor type systems this is going to see a larger quantity of products, installed over a larger area, almost invariably requiring rock-breaking excavators, drilling rigs, or both. To recap that’s lots of expenditure on products (that are vulnerable to thieves or vandals), lots of expenditure on labour and plant, and lots of time consumed to complete the installation.

Then again you could use an Earthing Services product solution, which is overwhelmingly cheaper on time, labour and plant. No excavation. No drilling. With ConduForm conductors can be “glued” directly on to rock; not only is it effective at safely managing fault current, it’s also highly resistant to even the most concerted attacks if thieves or vandals attempt to steal the copper within.

To summarize a ConduForm installation vs. conventional methods is:

- Safer for the installation team

- Easier for the installation team

- Faster for the installation team to complete

- Requires fewer installation engineers

- Requires no excavation or drilling plant, or its associated financial and time costs

- Has a significantly longer service life

- Is less vulnerable to thieves and vandals

- Is more effective and reliable

To anyone aware of these technological and methodological advances using the traditional approach looks exactly like it should: outdated.

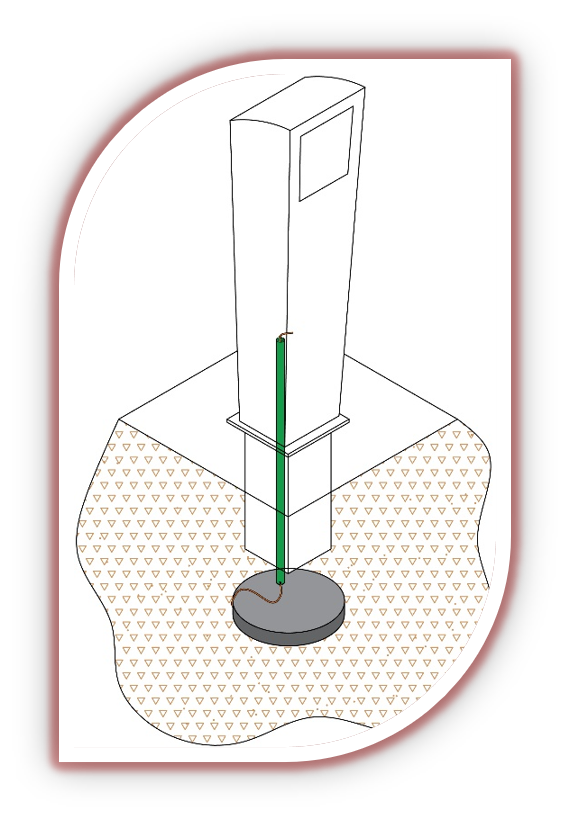

Electrical Vehicle Charginging Points: Earthing without rods - safer, faster and more effective earthing

Earthing Services is committed to elliminating the health and safety risks associated with earth rods. Using transferable products and methods it is now considerably safer for installers to create a permanent and safe electrical earth, meaning users of protected infrastructure will never be at risk due to an unknown deteriorated rod-type system. A great case study for earthing without rods has been our work in electrical vehicle charging points.

The increasing popularity of electrical vehicles has seen a comparably growing demand for charging points. Commercial charging stations have to be able to provide a stable service to their customers, which is not subject to operational downtime for earthing reasons. Domestic charging points have to function effectively in order for the resident to be able to travel. Both of these varieties of installation are susceptible to the risks associated with conventional earthing products. In many domestic installations it is impractical or potentially hazardous to drive earth rods, whereas in commercial installations they may be subject to potentially corrosive environments. Earthing Services has developed a number of high performance, cost-effective, reliable, and fast methodologies for earthing electrical vehicle charging installations without the need for conventional metallic conductors. Avoiding the threats of corrosion, the hazards of driving rods where unknown services are present, and the deterioration of earthing performance makes the ConduDisc and our other products highly attractive options for any party responsible for installing or owning this variety of infrastructure.

Protection for exposed cable or conductors, such as rail bonding / coupling

Anyone working in the electrical safety sector is well aware of the threat of thieves and vandals to any exposed conductor. This is especially true for rail infrastructure where cables providing equipotential bonds / couples (such as those between the running rails, or between the tracks, or indeed any adjacent infrastructure back to the rails) are regularly stolen, causing significant cost and disruption to commuters.

It is worth clarifying, when copper is used for electrical safety it is installed to save lives and if it is not there any more then people can suffer. It is easy to consider rail operators as faceless, wealthy companies that can afford to replace stolen copper, but these are the same companies publicly criticised every time rail fares rise.

Copper is a valuable commodity and it is expensive to constantly replace and unsurprisingly those costs are handed on to the customers. Another aspect to consider is that faceless wealthy companies have faces, and the faces belong to the people that work for them, undertaking often dangerous work to ensure that others are safe. The guy with the spanner in his hand at 3am on a winter morning is not a corporate bigwig, and even corporate bigwigs do not deserve to be victims of crime, otherwise those crimes would not be deemed criminal behaviour at all. Copper theft is frustratingly overlooked or dismissed because it is seen as “free money lying on the railway”, Earthing Services knows that it is not, it is a parachute, a brake cable, a seat belt, or a life raft. It is there for the expressed purpose of keeping people safe. With ConduForm protecting exposed conductors then they will continue to keep people safe, and infrastructure functioning.

Corrosion protection for direct buried steel power transmission infrastructure

The corrosion of direct buried steel power transmission infrastructure is an endemic problem for the utilities industries. For years the only answer seemed to be that the infrastructure would last as long as it could but when the corrosion reached a certain level which began to threaten structural stability and therefore safety it would be replaced.

One option that has been explored to combat this problem is the use of insulating coatings, which will prevent corrosion associated with current discharge. This variety of technology has been used to varying degrees of success on light rail infrastructure for some time for the purpose of stray current control. The problem with these coatings is that they can be easily scratched or damaged and whenever there is a penetration of the coating that becomes a source of leakage. Back to the example of light rail, this is one of the reasons that usually when such coatings are used on the running rails a secondary insulating layer is applied, before a tertiary collection measure is then adopted for current still escaping. When it comes to transmission infrastructure the scratch or break in the insulating coating that becomes the source of leak also becomes a point of corrosion. This presents a concerning threat as the affected utilities may presume that the corrosion checks prescribed are no longer required as a control measure has been put in place, only for that measure to continue to result in corrosion.

Earthing Services have a solution to this problem. It halts corrosion for the duration of the transmission infrastructure’s service life, which can be extended as corrosion is no longer going to require earlier replacement.

As you might expect from Earthing Services, the system also protects infrastructure from the threats of fault current discharge. It’s simple to install and requires no maintenance.

Reusable earthing for temporary sites and Renewable Energy applications

The majority of electrical earthing / grounding systems are put in the ground with the expectation that they will be there forever. If traditional or conventional conductors and methods are used then there is likely to be a far shorter functioning service life on the earthing system than the element that it is protecting. Anyone wanting to obtain the longest lasting earthing system service life should get in touch. That being said some sites may only exist for a few months, or perhaps a handful of years and the prospect of installing invasive traditional systems are likely to be wasting time and money. By using the ConduDisc smart companies are creating fast, easy and reliable earthing systems that require significantly less invasive installation. What’s more in many cases the ConduDisc can be removed at the end of the temporary site’s service life and be reused at the next destination.

Shallow excavation earthing

Whether it is due to a small footprint, underground service or infrastructure, or sub-surface rock, often earth rod electrodes are an impractical conductor in electrical earthing systems or lightning protection earth termination networks. To combat this Earthing Services has developed a range of shallow excavation earthing measures, and these do not require any significant reliance upon the usage of copper or metallic conductors. One of the most impressive attributes of this method is the speed with which they can be installed. Shallow excavation earthing either requires very little dedicated footprint or makes use of other excavations that are being undertaken for different purposes. An easy way of conceptualising this is a cable trench or foundation excavation. By utilising these other opportunities to increase an earthing system’s contact surface area our shallow excavation earthing systems have saved our clients significant time and financial costs, whilst providing them with a superior earthing system. None of the parties who have adopted this approach have returned to conventional methods or products.

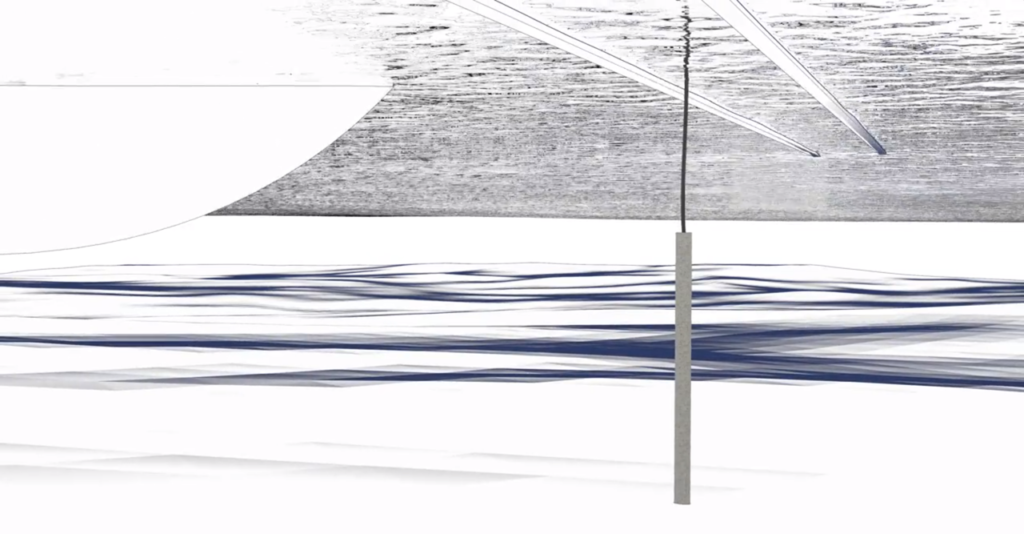

Earthing in marine environments

Occasionally a functional earth is required in marine-type environments; it sounds impossible doesn’t it? Achieving in a way of safely discharging electrical current in a location where there isn’t any soil to disperse it into? Well with the marine electrode it’s now possible. What’s more it’s incredibly easy to install, in fact as difficult as rolling a cut log. Once the electrode has been tethered at surface level and been rolled into the body of water it will descend until it makes contact with the river, sea, lake or marina bed and then it will bind into that medium. Like all of these solutions it’s really easy to install, has a really long service life, and most important of all, highly effective.

Overcoming earth / ground rod risks

Earth rods have been used in one form or another since the origins of earthing / grounding. They are so well established that they are specified and used almost without consideration from their inherent, and significant limitations. In much the same way that as human civilisation has improved at dentistry since 1752, so too has research into varieties of conductors and methods of installing them.

A recent report by a Safety Inspector detailed concerns about the use of earth rods:

- Danger to personnel and infrastructure from hitting unknown cables, pipes or other subterranean elements deleterious to health that may further impact dependent parties.

- Danger to installation teams using heavy hammer-type tools, both in terms of RSI and incidental injury from a mis-hit.

- Danger to installation teams using breaker-type hydraulic power tools, even if abiding by exposure limits.

- Slips, trips and falls from unseen power lines feeding breaker-type hydraulic power tools.

- Hearing damage from the use of breaker-type hydraulic tools both from the device itself and onsite generators.

- Danger to site/structure/dependent users, passersby or trespassers in the event of an earth fault where a deteriorated earth rod(s) is insufficient to effectively manage the fault.

By using our products and methods all of these hazards, and many more, are removed and do not need to be considered in RAMS. Furthermore on an insurance level the liability risks are also removed.

Sector leading Personal Protective Earthing / Grounding for OHL workers

Power transmission workers face electrical safety challenges of a greater magnitude than nearly any other person working in the electrical sector. The consequences of human error or equipment failure are all too often fatal, and as an industry power transmission utilities need to do more to protect their staff, but up to now there has been insufficient support from industry. This is no longer the case. Using this combination of easier working methods, more effective and reliable products, and an integrated approach means that every transmission worker will get home safely at the end of the day, and nobody should have to expect anything less than that.